- Introduction to laser cleaning technology

- Advantages of laser cleaning in comparison to traditional methods

- Corrosion prevention with laser cleaning

- Comparison of different types of lasers used for cleaning cooling towers

- The role of maintenance schedules in maximizing the benefits of laser cleaning

- The role of predictive maintenance in optimizing laser cleaning schedules

- Potential for reducing the risk of fouling with laser cleaning

- Reduction of downtime with laser cleaning

Introduction to laser cleaning technology

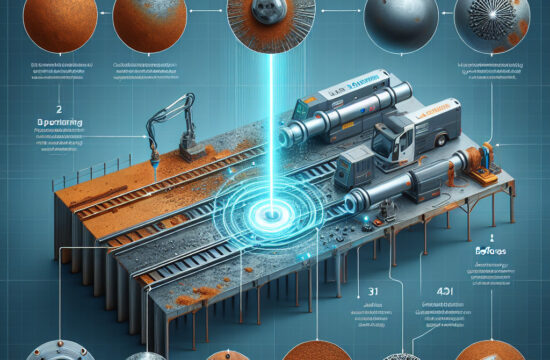

How Does Laser Cleaning Work?

Laser cleaning works by using a high-powered laser beam to vaporize or ablate the unwanted material from the surface. The laser beam is focused on the target area, where it heats and breaks down the contaminants, leaving behind a clean surface. This process is precise and can be controlled to remove only the desired material without affecting the substrate.

Benefits of Laser Cleaning Technology

- Non-contact cleaning method

- Environmentally friendly – no chemicals or abrasives needed

- Highly efficient and precise cleaning

- Can be used on a variety of surfaces, including metals, plastics, and ceramics

- Reduces the need for manual labor and costly maintenance

Applications of Laser Cleaning

Laser cleaning technology is used in a wide range of industries, including automotive, aerospace, electronics, and conservation. It can be used to clean rust from metal surfaces, remove paint from aircraft components, and restore historical artifacts without causing damage.

Future of Laser Cleaning Technology

As technology continues to advance, laser cleaning is expected to become even more efficient and cost-effective. Researchers are exploring new applications for laser cleaning, such as removing graffiti from buildings, cleaning delicate electronic components, and even sterilizing medical equipment.

In conclusion, laser cleaning technology is a versatile and innovative method for removing unwanted materials from surfaces. Its non-contact, environmentally friendly approach makes it a preferred choice for industries looking for efficient and precise cleaning solutions.

#laser #cleaning #technology #surface #contaminants #efficient #precise #noncontact #environmentallyfriendly #applications #future

frazy kluczowe:

– Advanced laser cleaning technology

– Non-contact surface cleaning

– Environmentally friendly cleaning method

– Precision laser cleaning solutions

– Industrial applications of laser cleaning technology

Advantages of laser cleaning in comparison to traditional methods

1. Non-contact cleaning: Laser cleaning is a non-contact process, which means that there is no physical contact between the cleaning tool and the surface being cleaned. This eliminates the risk of damage to delicate surfaces and ensures a gentle and precise cleaning process.

2. Environmentally friendly: Unlike traditional cleaning methods that often involve the use of harsh chemicals and solvents, laser cleaning is a clean and environmentally friendly process. It does not produce any waste or harmful emissions, making it a sustainable and eco-friendly cleaning solution.

3. High precision: Laser cleaning offers unparalleled precision and control, allowing for the removal of contaminants with pinpoint accuracy. This makes it ideal for cleaning intricate and complex surfaces that are difficult to clean using traditional methods.

4. Efficiency: Laser cleaning is a highly efficient process that can remove contaminants quickly and effectively. It can significantly reduce cleaning time and labor costs, making it a cost-effective solution for a wide range of applications.

5. Versatility: Laser cleaning can be used on a variety of materials, including metals, plastics, ceramics, and composites. It is suitable for a wide range of applications, from industrial cleaning to restoration and conservation projects.

Overall, laser cleaning offers a number of advantages over traditional cleaning methods, including non-contact cleaning, environmental friendliness, high precision, efficiency, and versatility. With its ability to clean a wide range of materials quickly and effectively, laser cleaning is quickly becoming the preferred choice for many industries.

#laser #cleaning #advantages #technology #environmentallyfriendly #precision #efficiency #versatility

frazy kluczowe:

– laser cleaning technology advantages

– non-contact environmentally friendly cleaning

– high precision laser cleaning

– efficient and versatile laser cleaning solutions

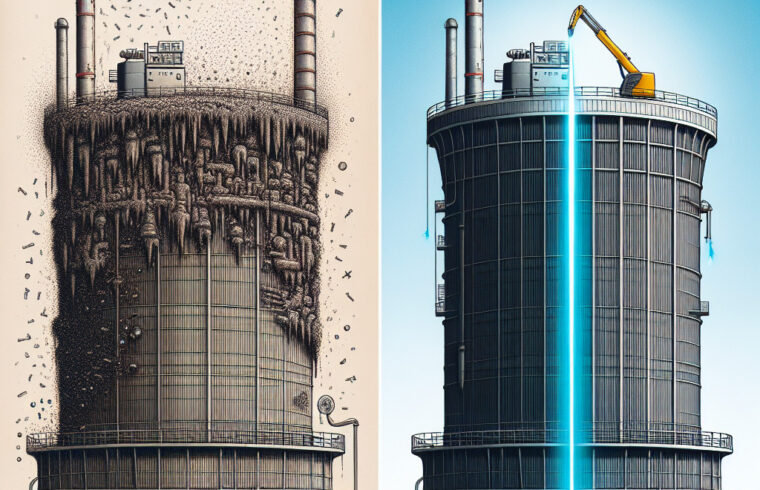

Corrosion prevention with laser cleaning

One of the key advantages of laser cleaning is its precision. The laser beam can be focused to a very small spot size, allowing for targeted cleaning of specific areas without affecting the surrounding material. This makes it ideal for removing corrosion from intricate parts and hard-to-reach areas.

Another benefit of laser cleaning is its efficiency. Unlike traditional methods such as sandblasting or chemical cleaning, laser cleaning does not produce any waste or require the use of harmful chemicals. This makes it a more sustainable and cost-effective solution for preventing corrosion.

In addition to preventing corrosion, laser cleaning can also improve the overall appearance and performance of metal surfaces. By removing contaminants and oxides, it can restore the original finish of the material and enhance its durability and longevity.

Overall, laser cleaning is a highly effective method for preventing corrosion and maintaining the integrity of metal surfaces. Its precision, efficiency, and environmental friendliness make it a preferred choice for industries looking to protect their assets from the damaging effects of corrosion.

Keywords:

- Corrosion prevention

- Laser cleaning

- Metal surfaces

- Contaminants

- Oxides

Long-tail phrases:

- Preventing corrosion with laser cleaning

- Benefits of laser cleaning for corrosion prevention

- Efficiency and precision of laser cleaning in corrosion prevention

#corrosion #prevention #laser #cleaning #metal #surfaces #contaminants #oxides #efficiency #precision #environmental #friendly #longevity #durability #sustainable #cost-effective #industries #damage #rust #appearance #performance #integrity #assets

Comparison of different types of lasers used for cleaning cooling towers

| Type of Laser | Advantages | Disadvantages |

|---|---|---|

| CO2 Laser | High precision cleaning | High cost |

| YAG Laser | Fast cleaning speed | Limited effectiveness on certain materials |

| Fiber Laser | Low maintenance | Limited power output |

Each type of laser has its own unique set of advantages and disadvantages. The CO2 laser is known for its high precision cleaning capabilities, making it ideal for removing tough deposits from cooling towers. However, the high cost of CO2 lasers can be a barrier for some users. The YAG laser, on the other hand, offers fast cleaning speed but may have limited effectiveness on certain materials. The fiber laser is a popular choice for its low maintenance requirements, but it may have limited power output compared to other types of lasers.

When choosing a laser for cleaning cooling towers, it is important to consider the specific requirements of the task at hand. Factors such as the type of material being cleaned, the size of the cooling tower, and the budget available will all play a role in determining the most suitable type of laser for the job.

In conclusion, there are several types of lasers that can be used for cleaning cooling towers, each with its own set of advantages and disadvantages. By carefully considering the specific requirements of the task at hand, users can select the most appropriate type of laser for optimal cleaning results.

#coolingtowers #lasercleaning #maintenance #efficiency

Keywords: cooling towers, lasers, cleaning, maintenance, efficiency

Long-tail phrases: comparison of different types of lasers, advantages and disadvantages of laser cleaning, factors to consider when choosing a laser for cleaning cooling towers.

The role of maintenance schedules in maximizing the benefits of laser cleaning

Benefits of regular maintenance schedules for laser cleaning equipment:

1. Preventive maintenance helps to identify and address potential issues before they escalate, reducing the risk of costly repairs or downtime.

2. Regular cleaning and calibration of the laser system ensure consistent and efficient performance, leading to better cleaning results.

3. Proper maintenance extends the lifespan of the equipment, maximizing the return on investment.

4. Compliance with manufacturer recommendations for maintenance can help maintain warranty coverage and ensure safety.

Key components of a maintenance schedule for laser cleaning equipment:

1. Regular inspection of the laser system components, including the laser source, optics, and cooling system.

2. Cleaning and alignment of the optics to maintain optimal beam quality and focus.

3. Calibration of the laser power and pulse settings to ensure consistent cleaning results.

4. Checking and replacing consumable parts, such as protective windows and filters, as needed.

5. Monitoring and recording performance metrics, such as cleaning speed and efficiency, to track equipment performance over time.

Implementing a maintenance schedule for laser cleaning equipment:

1. Create a detailed maintenance plan that outlines specific tasks, frequency, and responsible personnel.

2. Schedule regular maintenance intervals based on the manufacturer’s recommendations and usage patterns.

3. Train operators and maintenance staff on proper cleaning procedures and equipment handling.

4. Keep detailed records of maintenance activities, including dates, tasks performed, and any issues encountered.

5. Monitor equipment performance and adjust the maintenance schedule as needed to optimize cleaning efficiency.

By implementing a proactive maintenance schedule for laser cleaning equipment, users can maximize the benefits of this advanced cleaning technology. Regular maintenance not only ensures consistent and efficient performance but also extends the lifespan of the equipment, ultimately saving time and money in the long run.

#laser #cleaning #maintenance #schedule #equipment

frazy kluczowe:

– Laser cleaning equipment maintenance schedule

– Benefits of regular maintenance for laser cleaning

– Maximizing efficiency with laser cleaning maintenance schedule

The role of predictive maintenance in optimizing laser cleaning schedules

Another important aspect of predictive maintenance is its ability to reduce the risk of unexpected breakdowns. By monitoring equipment performance and identifying potential issues before they escalate, maintenance teams can address problems proactively and prevent costly downtime. This not only saves time and money, but also helps to extend the lifespan of laser cleaning equipment.

Furthermore, predictive maintenance can help to improve the overall efficiency of laser cleaning processes. By identifying and addressing issues before they impact performance, maintenance teams can ensure that equipment is operating at peak efficiency. This not only improves cleaning results, but also reduces energy consumption and extends the lifespan of equipment.

Table 1: Predictive maintenance benefits

| Benefit | Description |

|---|---|

| Efficient scheduling | Optimizes cleaning tasks |

| Reduced breakdowns | Prevents unexpected downtime |

| Improved efficiency | Enhances cleaning process |

In conclusion, predictive maintenance plays a crucial role in optimizing laser cleaning schedules. By using data-driven insights and advanced analytics, maintenance teams can improve efficiency, reduce downtime, and extend the lifespan of equipment. By proactively addressing issues before they escalate, predictive maintenance helps to ensure that laser cleaning processes run smoothly and effectively.

#predictivemaintenance #lasercleaning #optimization #efficiency #downtime #productivity #equipmentlifespan #dataanalysis

słowa kluczowe: predictive maintenance, laser cleaning, optimization, efficiency, downtime, productivity, equipment lifespan, data analysis

frazy kluczowe: role of predictive maintenance in laser cleaning, optimizing cleaning schedules with predictive maintenance, benefits of predictive maintenance in laser cleaning, predictive maintenance for efficient laser cleaning, improving efficiency with predictive maintenance in laser cleaning.

Potential for reducing the risk of fouling with laser cleaning

When surfaces become fouled with contaminants such as dirt, grease, or other substances, it can lead to a range of problems. Fouling can reduce the efficiency of equipment, cause corrosion, and even pose health risks in some cases. Traditional cleaning methods often involve the use of harsh chemicals or abrasive materials, which can be damaging to both the environment and the surfaces being cleaned.

With laser cleaning, however, these issues can be avoided. By using a focused beam of light to vaporize contaminants on a surface, laser cleaning can effectively remove fouling without the need for chemicals or abrasive materials. This not only reduces the risk of damage to the surface being cleaned but also eliminates the need for potentially harmful cleaning agents.

Furthermore, laser cleaning is a highly precise process, allowing for targeted removal of fouling without affecting the underlying surface. This level of precision makes laser cleaning ideal for use on delicate or intricate surfaces where traditional cleaning methods may not be suitable.

In addition to its effectiveness in removing fouling, laser cleaning also offers a number of other benefits. For example, it is a fast and efficient process, allowing for rapid cleaning of surfaces with minimal downtime. It is also a non-contact method, meaning that it can be used on surfaces that are difficult to access or that may be damaged by traditional cleaning methods.

Overall, the is significant. By offering a fast, efficient, and environmentally friendly alternative to traditional cleaning methods, laser cleaning has the potential to revolutionize the way we clean surfaces and reduce the impact of fouling on equipment and infrastructure.

Hashtags: #laser #cleaning #fouling #environmentallyfriendly

Keywords: laser cleaning, fouling, surface cleaning, environmentally friendly, precision cleaning

Long-tail phrases: potential for reducing fouling, laser cleaning benefits, environmentally friendly cleaning solutions

Reduction of downtime with laser cleaning

Another advantage of laser cleaning is its precision and effectiveness. Laser beams can be precisely controlled to target specific areas on a surface, removing contaminants with minimal impact on the underlying material. This results in a more thorough and efficient cleaning process compared to traditional methods such as abrasive blasting or chemical cleaning.

Furthermore, laser cleaning is a non-contact process, meaning that there is no physical contact between the cleaning equipment and the surface being cleaned. This reduces the risk of damage to delicate or sensitive materials, further minimizing downtime and maintenance costs.

In addition to reducing downtime, laser cleaning also offers environmental benefits. Traditional cleaning methods often involve the use of harsh chemicals or abrasive materials that can be harmful to the environment and pose health risks to workers. Laser cleaning, on the other hand, is a clean and environmentally friendly process that does not produce any waste or emissions.

Overall, the use of laser cleaning technology can help companies reduce downtime, increase productivity, and improve overall efficiency in their operations. By investing in laser cleaning equipment, businesses can save time and money while also reducing their environmental impact.

#laser #cleaning #downtime #efficiency #productivity #environmentallyfriendly

frazy kluczowe:

– reducing downtime with laser cleaning

– benefits of laser cleaning in industrial applications

– improving efficiency with laser cleaning technology

– environmental advantages of laser cleaning

– cost savings through laser cleaning implementation

- The benefits of outsourcing to a Software Development Company - 29 September 2025

- Laser cleaning for removing rust and corrosion from metal surfaces - 12 July 2024

- The impact of laser cleaning on the efficiency of cooling towers. - 8 April 2024